Aluminum foil bag

Key words:

Classification:

Product Introduction

Material composition

Aluminum foil bags are usually multi-layer composite materials, mainly including aluminum foil layers. Aluminum foil is made of metal aluminum directly rolled into a sheet, it has good barrier properties, can block oxygen, water vapor, light and so on. In addition to the aluminum foil layer, there will also be a plastic film layer, such as polyethylene (PE), polypropylene (PP), etc. These plastic layers can provide flexibility, toughness and heat sealability, allowing the bag to be easily formed and effectively sealed.

Characteristics

High barrier property

Aluminum foil bags have excellent barrier properties to oxygen. For example, in food packaging, it can prevent oxygen from entering the inside of the package, thereby delaying the oxidation process of food, such as foods containing fats (such as nuts, fried foods, etc.) if exposed to oxygen is prone to rancidity, aluminum foil bags can be very good Protect them.

It also has a good barrier to water vapor. For some products that need to be kept dry, such as desiccant packs for medicines and electronic products, aluminum foil bags can prevent external water vapor from entering and ensure that the internal environment is dry.

Can effectively block light, especially ultraviolet rays. This is a very important packaging material for some light-sensitive products, such as certain medicines, photographic films, etc., to prevent the product from deteriorating due to light.

Good mechanical properties

Aluminum foil bag has a certain strength and toughness. It can withstand a certain degree of extrusion, stretching and other external forces, and can protect the product from damage during transportation and storage. For example, in packaging some products with a certain weight and hardness, such as small tools, aluminum foil bags will not easily break.

Good heat sealing property

The sealing may be performed by a heat sealing process to form a relatively closed package space. The strength of heat sealing can ensure that the bag will not crack during normal use and transportation, and the heat sealing process is relatively simple and efficient, suitable for large-scale industrial production.

Application areas

Food Packaging

Used for packaging various foods, such as meat products, snack foods, coffee, tea, etc. For example, the use of aluminum foil bags for coffee packaging can maintain the aroma of coffee and prevent aroma loss and oxidation. The tea is packed in aluminum foil bags, which can isolate light and oxygen and maintain the color and taste of the tea.

Pharmaceutical Packaging

Many drugs require a good packaging environment to ensure their efficacy and quality. Aluminum foil bag can provide stable storage conditions for drugs, prevent drugs from moisture, oxidation and light decomposition. For example, some capsules, tablets and other drugs, aluminum foil bag packaging can extend the shelf life of drugs.

Electronic components packaging

Electronic components have high requirements for the environment, such as moisture-proof, anti-static, etc. Aluminum foil bag can prevent electronic components from being damp, and it has a certain ability to shield static electricity, which can protect the safety of electronic components during transportation and storage. Electronic components such as mobile phone chips and computer memory chips can be packaged in aluminum foil bags.

Product advantages

Baihui advantage lets you rest assured to choose

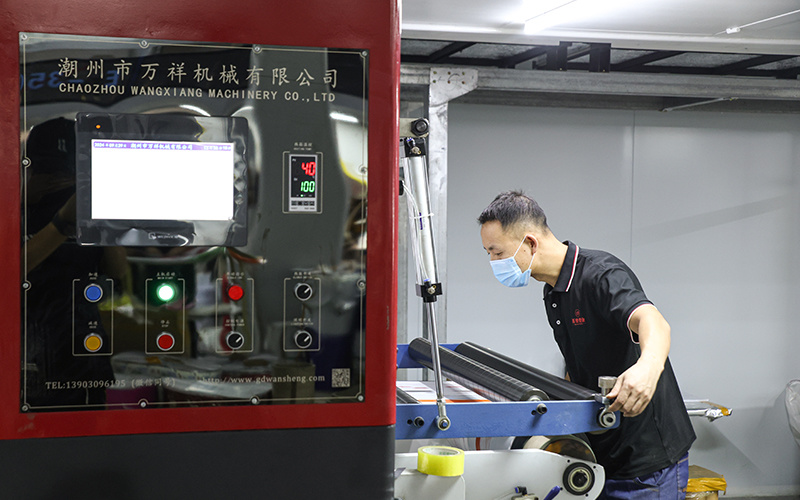

Hebei Baihua Plastic Industry Co., Ltd. was established in 2021 and is located in the East District of the Economic Development Zone of Fucheng County, Hengshui City. It covers an area of 30 acres, with a production workshop of 18000 square meters and a scientific research building with a construction area of 2200 square meters. The total investment is 0.12 billion yuan.

A modern comprehensive printing company integrating R & D, design, printing, bag making, testing and after-sales service has introduced a number of full-automatic high-speed printing machines, solvent-free laminating machines, self-supporting zipper machines, eight-edge bag-making machines and advanced Supporting equipment, equipped with VOC purification production workshop, new product research and development room, laboratory, etc., with a total equipment investment of more than 4000 million yuan.

Factory direct sales

Selected Raw Materials

Processing customization

Durable

Intimate after-sales

Timely delivery

Plant environment

Customized delivery process

Our main products include plastic-plastic composite packaging bags and coiled materials, retort packaging bags, general aluminum foil packaging bags and coiled materials and aluminum foil retort packaging bags and coiled materials, customized self-supporting zippers and three-sided packaging bags, general plastic self-supporting zippers and three-sided packaging bags, special-shaped customized zipper self-supporting bags and suction nozzle bags, eight-sided sealing composite bags, etc.

Online Communication

Provide customized drawings

Merchant Quotation

Signing a contract

processing production

Packaging and distribution

Confirm receipt

Transaction success

Previous:

The next one:

immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!